New safety guide addresses deadly fluid power risks in NSW mining operations

, , , , ,

,

A new technical reference guide released by the NSW Resources Regulator is aiming to reduce serious injuries and fatalities linked to fluid power systems used in mining plant across the state.

Published in March 2025, the updated TRG 41 – Fluid Power Safety Systems at Mines replaces several previous guidelines and now sets out a consolidated, lifecycle-based framework for managing the risks associated with hydraulic and pneumatic energy systems.

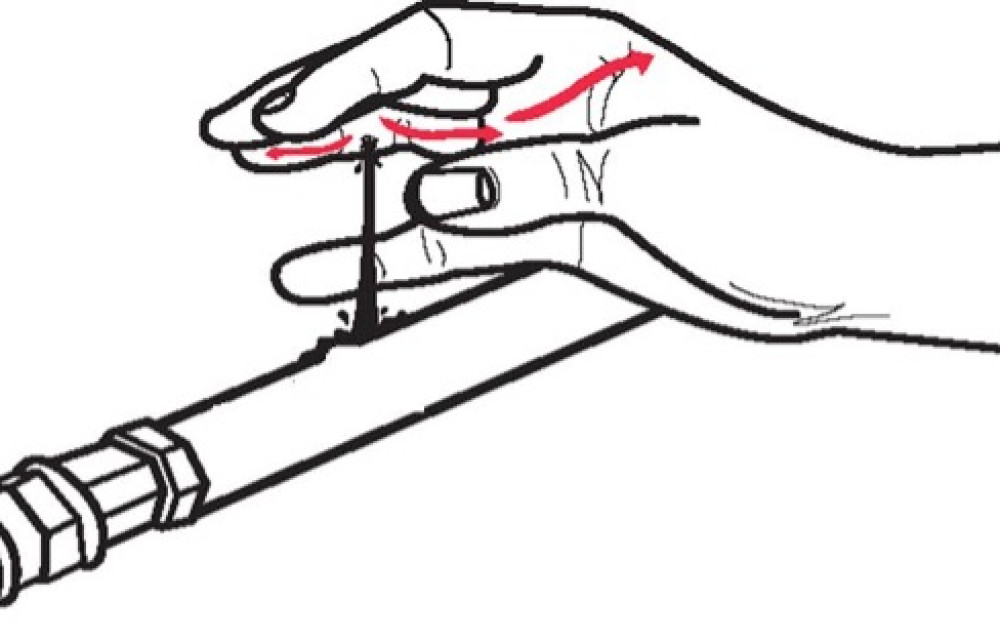

According to the NSW Resources Regulator, high-pressure fluid injection injuries remain among the most dangerous hazards in mining operations. These injuries—caused by fluid escaping at high velocity—can result in burns, amputations, eye injuries or even death.

The revised guide was released following a consultation process and now incorporates feedback from operators and safety experts across the sector. It supersedes previous Mining Design Guidelines MDG41, MDG3007, MDG10, and the MDG41-TR1 covering super staple lock fittings.

“This guide is designed to help mine operators and designers mitigate fluid power risks across the full plant lifecycle—from design and installation to operation, maintenance, and decommissioning,” the Regulator states in the document's foreword.

The 133-page guide addresses both immediate and latent hazards—ranging from hose failures and high-temperature fluids to control system malfunctions, pressure intensification, and unsafe maintenance practices.

Lifecycle safety approach

One of the most significant developments in the new guide is its emphasis on the lifecycle management of fluid power systems, with detailed requirements for design risk assessments, system schematics, and the creation of a 'plant safety file'—a structured record of specifications, risk controls, incidents, and changes.

Designers must now consider human factors, compatibility of fluids, and ergonomic layout of controls. They are also required to specify components based on rated working pressure and provide sufficient marking, labelling, and schematic documentation to prevent misuse or error.

New compliance expectations for hose assemblies and emergency stops

Given that hose failures are a leading cause of hydraulic incidents, the guide introduces strict rules for hose selection, installation, tagging, testing, and lifecycle replacement. All hose assemblies used in high-risk areas must now be tested and tagged, and pressure gauges are required to display safe operating zones.

The guide also mandates the inclusion of emergency stops and hydraulic isolation devices that can be locked and verified to ensure systems are de-energised during maintenance—a response to incidents where unexpected movement of plant has caused serious injury.

Updated longwall-specific protocols

The guide includes a section specific to longwall installations in underground coal mines, where high-pressure hydraulic systems are most concentrated. It recommends colour-coded hose assembly systems and unique coupling styles to prevent cross-connections and outlines procedures for de-pressurising leg cylinders during installation.

Industry obligations under WHS law

TRG 41 reiterates the legal responsibilities of designers, suppliers, and mine operators under the Work Health and Safety Act 2011 and the WHS (Mines and Petroleum Sites) Regulation 2022.

All fluid power equipment categorised as high risk must be designed, tested, and registered according to Australian standards, including AS 4343 for pressure equipment and AS/NZS 4024 for plant safety.

The guide is now the primary safety document referenced by the Resources Regulator for fluid power systems and is expected to become a benchmark across both surface and underground operations in NSW.

The full guide is available from the NSW Resources Regulator website: https://www.resources.nsw.gov.au/