Smart miners know one plan won’t cut it - stochastic thinking is helping them outsmart uncertainty, reduce risk, and mine with more confidence than ever

, , , , , , , , , , , , ,

, , , , , ,

, , , , , , , ,

For decades, mine planning has leaned heavily on deterministic models - tools that simplify the earth into a single version of the truth. But in a world where orebody variability, grade uncertainty, and operational risk are constant companions, these traditional methods may no longer be enough. Enter stochastic mine planning, a data-driven approach that embraces uncertainty to improve decision-making and unlock value.

At the forefront of this shift is KPI Mining Solutions, COSMO Stochastic Mine Planning Laboratory of McGill University, and its mining industry consortium - a group that includes BHP, Newmont, Vale, Anglo American, AngloGold Ashanti, Iamgold, Kinross, and Agnico Eagle. This history is explained by Matheus Faria, Director of Technical Services at KPI Mining Solutions. With a background in mining engineering from Brazil’s Federal University of Minas Gerais, and a master’s in stochastic mine planning from the COSMO Lab, Matheus brings both academic insight and commercial experience to this evolving space.

"There's always going to be uncertainty in mining," Matheus said during a recent interview with The Rock Wrangler. "The real question is: can we make better decisions by accounting for it, instead of pretending it doesn’t exist?"

Bridging the divide between geology and planning

Mining companies are challenged by what Matheus describes as a "Chinese wall" between resource modelling teams and mine planners. "Very often, assumptions made and selected methods during the modelling process aren’t communicated or understood by planners," he explained. "And planners may not fully question or appreciate the limitations of the models they receive."

This disconnect can lead to a misrepresentation of the mineral resources, suboptimal decisions with costly consequences. Stochastic mine planning, Matheus argues, helps bridge that gap by allowing teams to evaluate and optimise production schedules across multiple scenarios that reflect real geological uncertainty.

From the lab to the pit

The foundation for KPI Mining Solutions was laid in the academic halls of McGill’s COSMO Lab, where Prof. Roussos Dimitrakopoulos develops research on stochastic mine planning optimization and stochastic orebody modelling over the last 20 years. After understanding the benefits of these technologies, the consortium said: “these stochastic approaches are great, but we need tools that can be used in practice”.. KPI was then selected to take the intellectual property developed at COSMO and built a commercial software platform around it," he said. "The mission was simple: make these advanced methods usable in the real world."

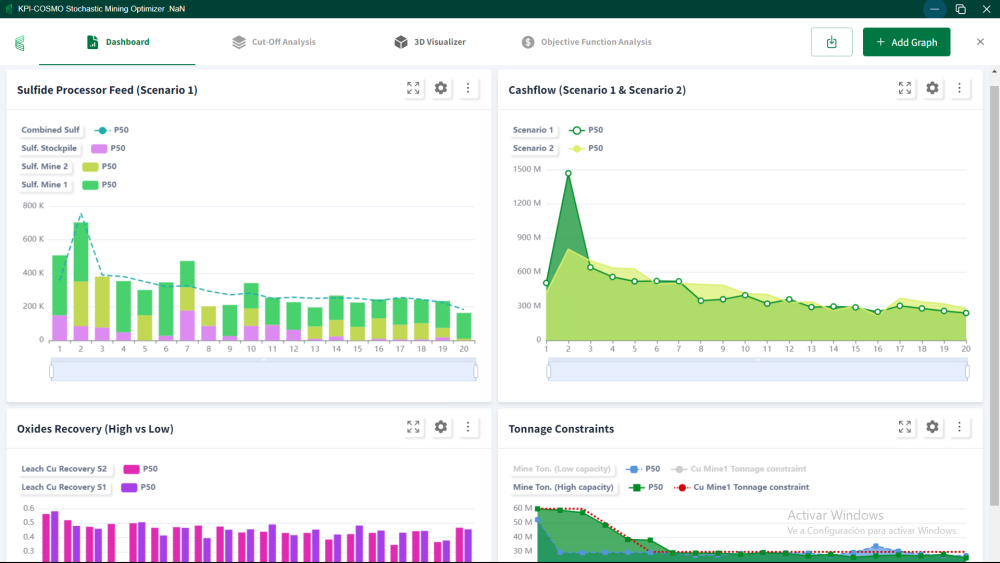

KPI-COSMO's platform focuses primarily on long-term production scheduling, helping clients benchmark traditional approaches against stochastic ones. "At first, most companies just want to compare," Matheus explained. "They run both schedules side-by-side to see where the differences lie and whether stochastic methods really offer a competitive edge."

The results have been compelling. Matheus highlighted one case in particular where a mine experienced unexpected waste material appearing within planned ore zones. "Their conventional model didn’t flag these intrusions," he said. "But the geostatistical simulations, based on the same exploration data, showed a probability of encountering that waste. When they compared our model to the grade control data, it was spot on."

Better models, better schedules

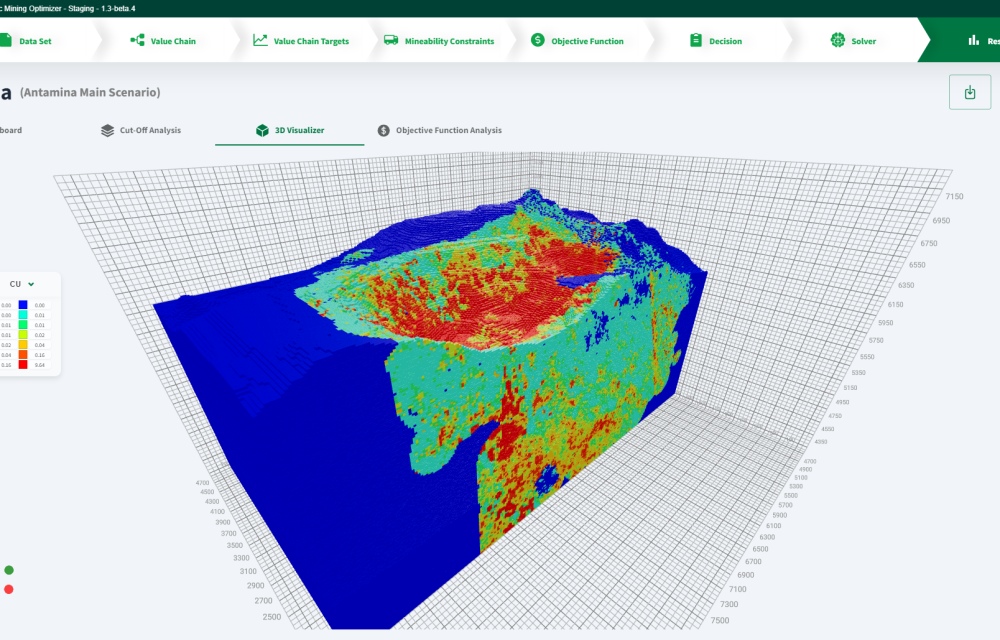

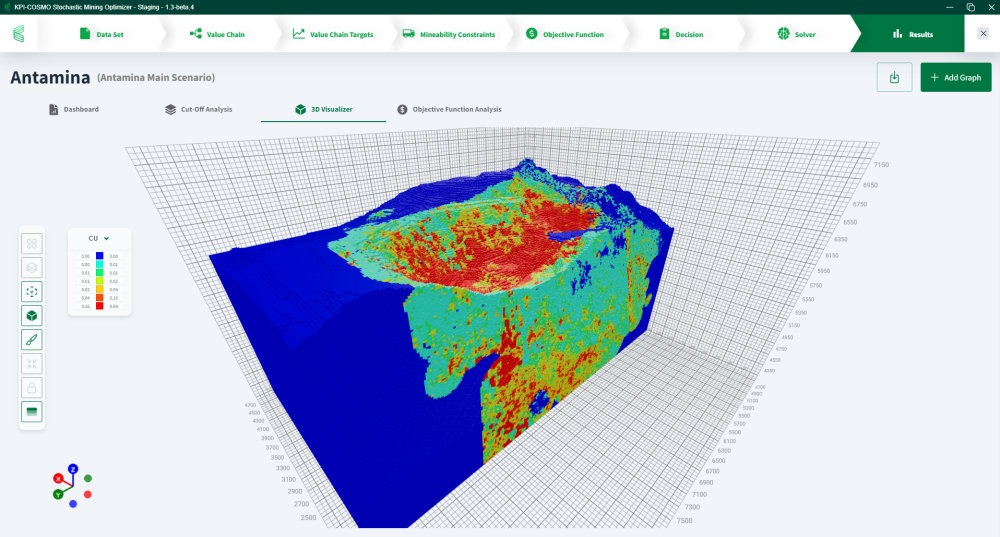

At the heart of stochastic planning is the use of geostatistical simulations rather than smoothed, kriged resource models. "Kriging tends to underestimate highs and lows and overestimate the average," said Matheus. "That might work for reporting, but it's not ideal for planning, and doesn’t allow for understanding and management of risk."

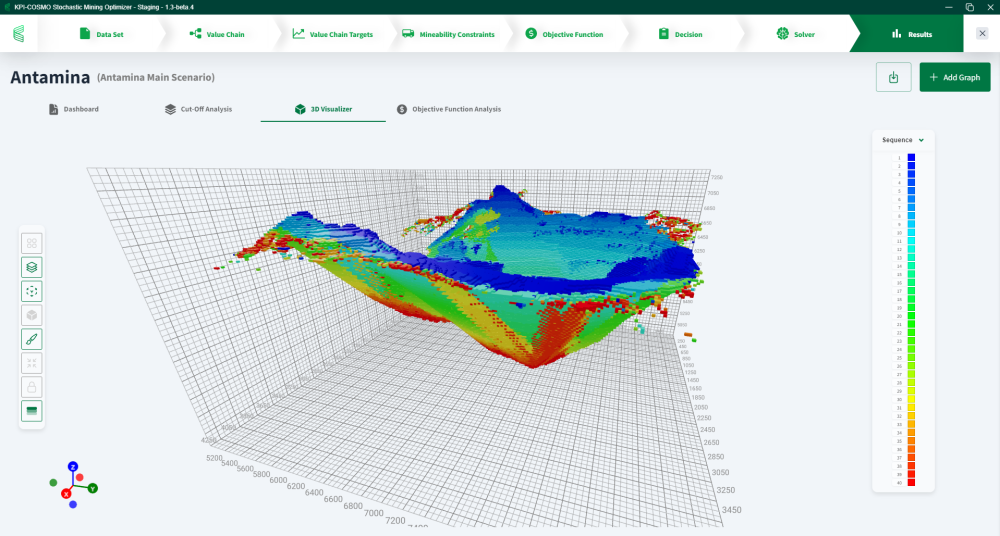

Simulations, by contrast, preserve spatial variability and provide a probabilistic view of the deposit. This enables two critical workflows: risk analysis and risk-optimised scheduling.

"We can take a deterministic schedule and test it against multiple simulated realities," said Matheus. "That tells us where the risks are highest, where we might need more drilling, or whether the plan is overly optimistic."

From there, the software can generate a new schedule - one that minimises risk across all possible scenarios. "It's a single plan that anticipates many outcomes," Matheus explained. "It’s still operationally feasible, but it’s also more resilient."

Challenging the status quo

While many mining companies are cautiously optimistic, Matheus acknowledges that change comes slowly. "Mining is a conservative industry. Even when people are aware of the methods, they want to see them working before they adopt them."

Still, momentum is building. Matheus cited growing interest from major operators, including those in the COSMO Lab consortium and others. "These companies are really driving innovation in this space," he said. "Some have been using stochastic methods internally for years now, not yet for reporting."

More recently, KPI has begun helping clients apply stochastic models earlier in the project lifecycle. "For exploration-stage assets, we can show a broader range of economic outcomes. That can speed up feasibility studies and help justify investment," he said.

Real-world integration

For those worried about overhauling existing systems, Matheus is quick to reassure. "We’re not trying to replace everything," he said. "Our tools work alongside conventional planning and design software. The main change is the order of operations and the probabilistic reporting.” In addition, traditional workflows, mine design comes early - sometimes before optimization. With stochastic planning, optimization drives design. "We use direct block scheduling, which means we optimise first, then design around the optimal plan," he explained.

The integration is still evolving, but KPI is working toward tighter links with short- and medium-term planning. "We’re also starting to simulate operational uncertainties like equipment performance and mill throughput," Matheus added. "It’s not just about grades anymore."

Looking ahead

So, what’s next for KPI Mining Solutions and COSMO Lab?

"We’re focused on improving computational performance and adding capabilities for underground mines and medium-term planning," Matheus said. "Each mining method comes with different constraints, so modelling them properly takes time."

Longer term, the vision gets even more ambitious. "We want to support near real-time decision-making," he said. "With the right data and machine learning, we could update plans dynamically based on sensor inputs, blast movement, or even process plant data."

The challenge, as always, is managing complexity without overwhelming users. But for Matheus, it’s worth the effort. "The more accurately we can model uncertainty, the better our decisions become. That’s what it’s all about."

As our conversation wrapped up, he offered one last reflection that captured the philosophy underpinning his work: "Uncertainty never ends. The key is learning how to live with it - and plan for it."