Tasmania’s next big tin thing combines green power, high grade and smart tech to shake up the global supply chain and put old-school miners on notice

, , , , , , , , , ,

,

, , , ,

A high-grade underground tin project in Tasmania is shaping up to be one of the most technically efficient and METS-driven developments in the sector, combining smart drilling, ore sorting technology, and a 100 percent renewable power supply to redefine what "green mining" looks like in the post-carbon economy.

The project in question is the Heemskirk Tin Project, owned and advanced by ASX-listed Stellar Resources (ASX: SRZ). Located just outside Zeehan on Tasmania’s West Coast, the deposit lies in a mature mining jurisdiction that already hosts nearby long-life underground operations like Renison Bell and Rosebery. But it’s what’s happening underground and inside the process flowsheets that’s catching industry attention.

From High-Grade Core to Ore Sorting Edge

At the recent RIU Sydney Resources Round-up, Stellar managing director Simon Taylor laid out the strategy: transition from explorer to developer by mid-2025, lean into ore sorting technology to slash waste volumes, and double output via smart mine planning and processing scale-ups. “We’ve proven up a high-grade resource with 97 percent cassiterite—a dream feedstock for gravity and ore-sorting circuits,” said Taylor.

The company’s updated scoping study outlines a 12-year mine life producing ~1,900 tpa of payable tin under base case conditions, with plans under the current PFS to ramp up to 3,000–3,500 tpa. Notably, Heemskirk’s ore sorting trials—using XRT sensors—have demonstrated a 2.4x uplift in head grade while rejecting up to 64% of the mass prior to processing. That’s game-changing for capex, opex, and ESG alike.

Fully Renewable and Highly Buildable

The Heemskirk site will tap directly into Tasmania’s 100 percent renewable energy grid, powered by hydro and wind within a 30km radius. It’s an advantage both operational and reputational, with OEMs and off-takers under growing pressure to source low-carbon critical minerals.

Site development will centre on conventional underground mining methods and a modular processing plant—with proposed infrastructure already mapped and a nearby MOU-secured site (Comstock) offering latent facilities including tailings storage, ROM pads, and grid connection.

What It Means for METS

For Australia’s METS sector, the project spells opportunity across:

-

XRT ore sorting systems and gravity circuit integration

-

Underground mining gear and long-hole stoping rigs

-

Modular plant construction and commissioning

-

Tailings solutions with a reduced footprint

-

Baseline environmental monitoring and permitting

-

Workforce accommodation and logistics

-

Automated ventilation and real-time monitoring tech

The project also highlights the increasing role of collaborative technology trials (e.g., ore sorting validation at Severn and Queen Hill zones), as operators seek to de-risk flowsheets and optimise upstream cost structures ahead of DFS.

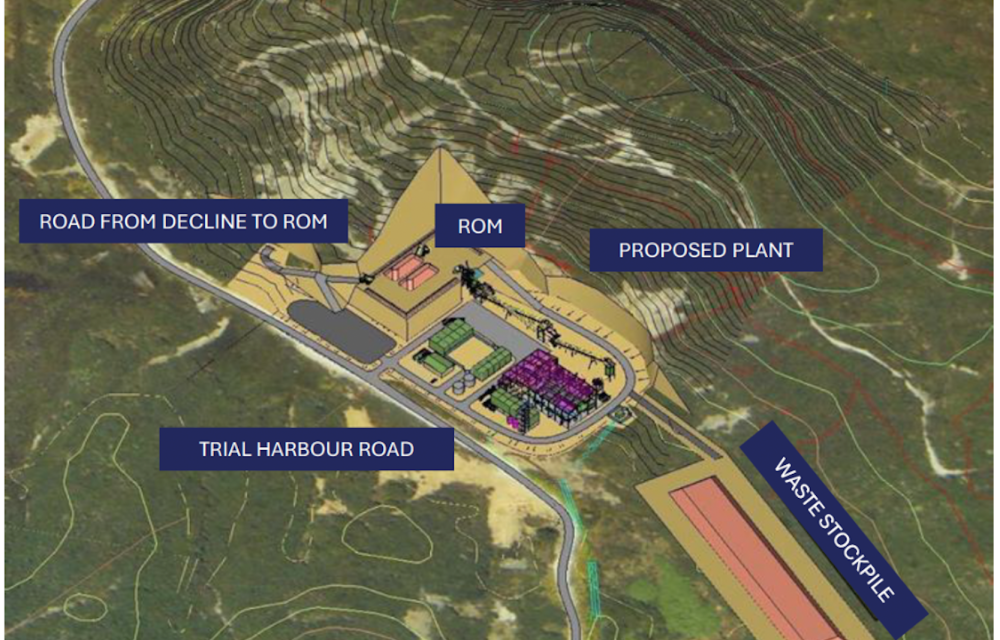

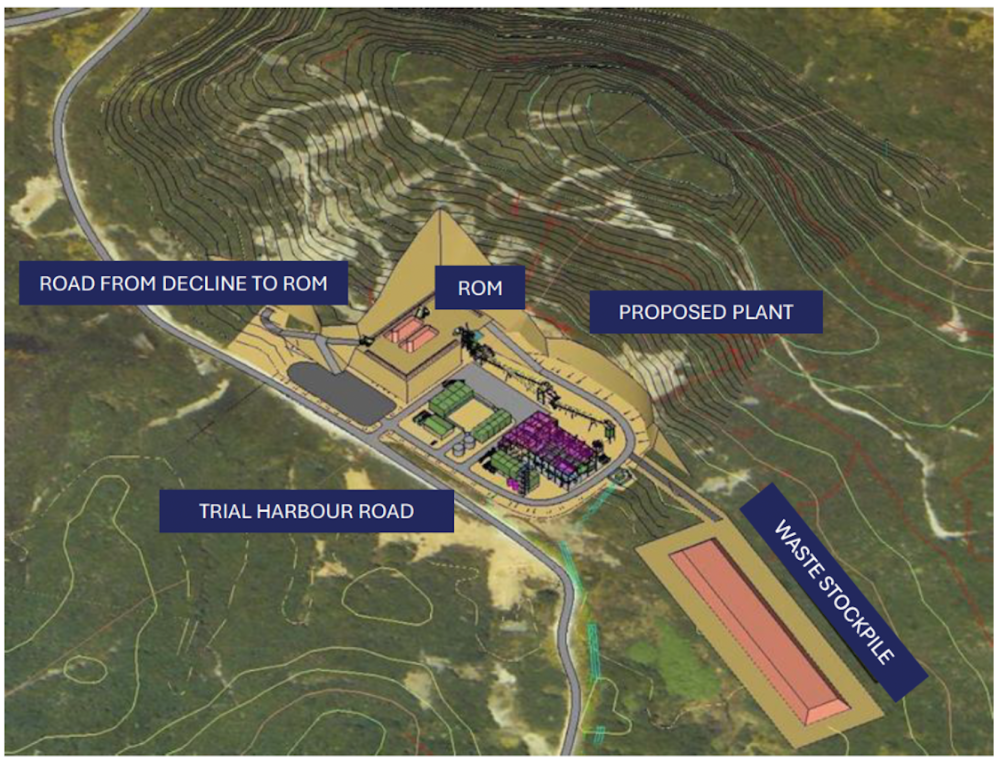

Site layout for the proposed Heemskirk Tin Processing Plant near Zeehan, Tasmania, showing key infrastructure including ROM pad, processing plant, haul roads, and waste stockpile adjacent to Trial Harbour Road.

What’s Next?

Stellar plans to complete its 9,500m PFS drilling campaign and release a resource upgrade in Q3 2025. The PFS—due in the second half of the year—will feed into a final investment decision likely in early 2026.

With institutional support in place (including Regal and Marford on the register), A$8.4M in the bank, and drilling hitting intercepts like 23.3m @ 2.20% Sn, the project is fast moving from prospect to producer.

“We’re in the right commodity, in the right place, at the right time,” said Taylor. For the METS sector, it’s a timely cue to start watching the Heemskirk story—and getting boots on the ground in Tasmania.