Long-life sand project in WA nears final approvals as Asia’s industrial demand collides with critical shortage of high-grade supply

, , , , , , , , ,

, ,

,

In the scrubby sands of Western Australia’s Mid West, a quietly ambitious mining development is nearing a final government tick — and it’s shaping up to be a masterclass in low-impact, high-efficiency industrial minerals extraction.

The Arrowsmith North Silica Sand Project — owned by VRX Silica (ASX: VRX) — is pushing toward production, with a final environmental decision sitting on the desk of WA’s Minister for Environment. If approvals land this quarter, the company plans to break ground within months and commission its 2Mtpa processing plant by late 2026.

So what makes this sand project stand out in a market dominated by iron ore and lithium headlines? One word: opportunity. High-grade, low-iron silica sand is in short supply — particularly across Asia, where foundries, solar panel makers and glass manufacturers are scrambling to secure long-term feed.

“This isn’t beach sand or desert sand — this is purpose-built material for the clean energy transition,” said managing director Bruce Maluish during a presentation at the RIU Sydney Resources Round-up 2025. “Asia’s running out, and we’ve got what they need — and in serious volume.”

Fit-For-Purpose Plant, Simple Flowsheet

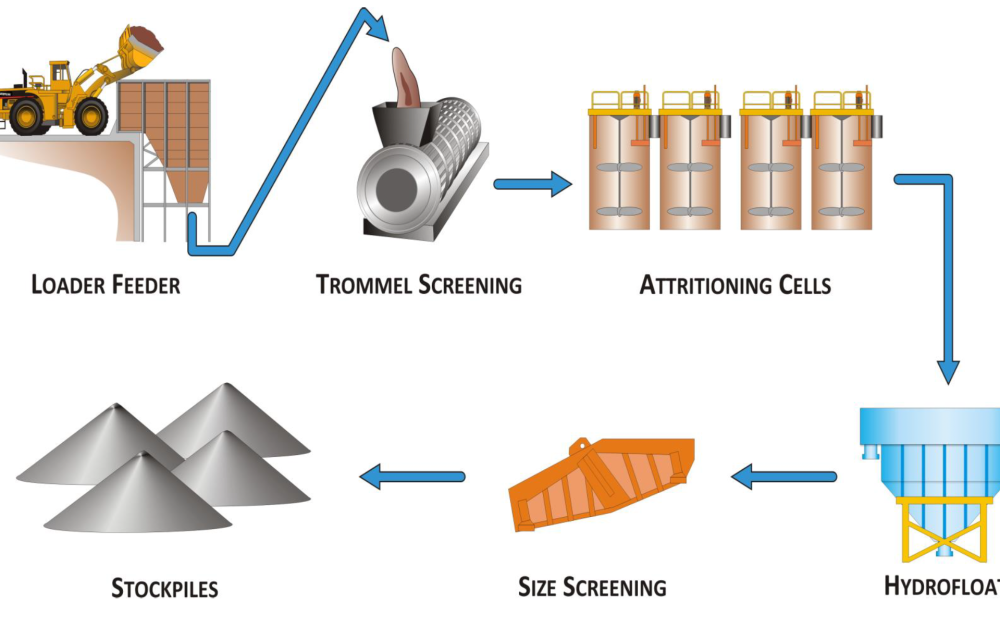

From an operational perspective, Arrowsmith North is a streamlined, low-impact operation. The deposit sits in loose, dry sand with vegetation no taller than waist height — allowing for easy overburden handling and rapid rehabilitation. Mining will use conventional dry excavation methods, feeding directly into a wet attritioning circuit.

The 2Mtpa plant design is already complete, with fabrication-ready engineering drawings in hand. Key features include:

-

Wet attritioning cells for grain polishing (no chemical reagents)

-

Multistage screening and classification to produce multiple grades

-

Dust-free operation, thanks to moisture-based processing

-

No tailings dam — rejected material is returned to mined areas

-

Low power consumption with planned hybrid gas-solar power at site

“It’s all water-based,” said Maluish. “No dust, no toxic chemicals, and no real complexity — which means it’s replicable across our other projects too.”

Water supply comes from an on-site bore drilled into the Yarragadee aquifer, delivering 90L/s, while power is expected to be generated via nearby gas wells or local tie-ins to WA’s Dampier-to-Bunbury pipeline. “We’ve got gas running right through the lease boundary — it’s as good as it gets for embedded energy,” he added.

Render of the proposed 2Mtpa processing plant at Arrowsmith North, featuring wet attritioning cells, clean water-based circuit, and modular site infrastructure designed for rapid deployment and low environmental impact.

Purpose-Built Rehab Method For Sand Country

One of the standout innovations is VRX’s Vegetation Direct Transfer (VDT) rehab system — designed specifically for WA’s sandy, shallow-rooted environments. A custom loader bucket lifts intact sods of vegetation and topsoil (3m x 3m x 400mm deep), which are relocated post-mining to preserve biodiversity.

This pre-strip-and-replace technique means rehab is effectively continuous — not something saved for end-of-mine-life. According to VRX, early trials have shown strong regeneration outcomes with minimal intervention.

“It’s a dead-simple method, but it’s been designed around the landscape. No windrows, no stockpiling topsoil, no seed mixes. Just lift and shift,” Maluish explained.

Foundry-Grade + Solar-Glass Feed

The product itself is anything but ordinary. Arrowsmith North will deliver multiple silica sand grades for glassmaking and foundry use — including custom sizing for Asia’s 3D-printed casting mould industry. Foundry-grade sand depends on grain shape, roundness and strength — and VRX’s feedstock hits the mark.

“Korea and Japan are panicking — they’ve got under 10 years of local supply left,” Maluish said. “We’re already in discussions to lock in long-term contracts for their automotive and shipbuilding foundries.”

But the real kicker is the company’s second project, Muchea, just 50km north of Perth. This ultra-high-purity silica deposit (208Mt @ 99.6% SiO₂) is earmarked for solar panel cover glass and downstream manufacturing opportunities. Letters of interest for over 13Mtpa have already landed.

WA’s low-cost LNG is a game-changer here. “Eighty percent of the cost of making glass is energy,” Maluish said. “We’ve got some of the cheapest LNG in the world — and that makes us attractive to international glassmakers.” VRX is already talking to global players interested in setting up shop in WA, citing the alignment with government clean energy manufacturing goals.

Downstream Vision: Silica Flour And Solar Glass

In addition to bulk sand exports, VRX is exploring downstream options including silica flour production — used in LCDs, semiconductors, and high-spec construction materials. With a WA Innovation Attraction Fund (IAF) grant secured, the company has trialled a one-tonne sample in Germany with promising results and is now shipping samples to interested offtakers.

The longer-term vision? Build an Australian supply chain for solar panel glass. “We can’t do it ourselves — a glass factory is a $500 million investment,” Maluish said. “But we can be the feedstock supplier that underpins it.”

Timing, Approvals, And METS Demand

Final approvals for Arrowsmith North are expected in Q2 2025, with a final investment decision to follow shortly after. AMC Consultants is finalising an independent technical review to support financing, and detailed permitting for water, mining and infrastructure is already in place.

For METS and contractor companies, this project represents a strong pipeline of procurement opportunities across:

-

Processing plant fabrication and installation

-

Conveyor systems and electricals

-

Mining services and site civils

-

Bore installation and water systems

-

Loader attachments and mobile plant

-

Power infrastructure (gas generation, hybrid solutions)

-

Environmental monitoring and rehab tech

During construction, the project will support around 100 jobs, with ~40 full-time roles in operations.

Wrangler’s Wrap

WA has sand — and Asia wants it. With a simple flowsheet, clever rehab method, and clear export demand, Arrowsmith North ticks all the boxes for a low-risk, high-demand industrial minerals project. Add in Muchea’s potential for downstream value and WA’s LNG cost advantage, and you’ve got the bones of a new clean energy supply chain starting right in the sand.

Want to track supplier packages, milestones and FID timing? Keep your boots on The Rock Wrangler — we’ll keep you updated.